Platinum casting grains enable jewelers and smiths to forge platinum items with the desired composition of platinum and base metals. Nowadays, platinum can be cast in small shops as long as you know what you’re doing. Ricardo Basta Eichberg was the first to cast platinum in 1986. He learned through trial and error before platinum casting machines were invented in the 1990s.

Bullion Trading LLC now stocks platinum casting grains to give our customers the option of creating platinum alloys with the composition they desire. We sell two types of platinum grains. They include the 95.2 pt. /4.8% Ru from Johnson & Matthey and 95% pt. /5% Ru from Umicore.

Platinum grains bought from us can be cast using machines which is the most preferred method. The machine enables rapid safe melting in a controlled atmosphere. Small shops that don’t have the money to buy machines depend on torch casting. The safest form of torch casting is vertical centrifugal casting.

The best torch for melting platinum grains is the one with a multiport or rosebud that is screwed on the torch as opposed to soldering. Torches with soldiered tips are avoided because they can be melted by the heat the platinum reflects and fall into the molten platinum. Furthermore, the torch you use should have a built-in flashback arrestor to prevent gases from flowing back into the flask. This may happen if the pressure changes.

When melting platinum casting grains, it’s important to select a suitable fuel. Experts discourage the use of acetylene torches. Acetylene has a high carbon content that is emitted when the fuel burns. Platinum will absorb the carbon leading to contamination and a brittle cast. Petrol and LPG can be used to melt platinum because they’re carbon-based fuels with lower carbon content compared to acetylene. However, these fuels have a longer melting time.

The recommended and most efficient way of melting platinum granules is with a mixture of hydrogen and oxygen as a fuel. This fuel is carbon-free and generates the hottest flames that melt platinum in seconds. The oven or kiln used should be capable of withstanding high temperatures.

To cast platinum granules into the right composition and shape you need platinum investment because it can withstand high temperatures compared to gypsum investment. Platinum investments come in two basic types they include acid-bonded and phosphate-bonded investments.

Alloys are also needed in casting both the 95.2 pt. /4.8% Ru from Johnson & Matthey and 95% pt. /5% Ru from Umicore. The casting temperature for platinum ranges from 850°F to 2,000°F depending on the type of investment used. The complexity and the weight of the grains also determine the temperature at which platinum melts.

Once you’re ready to cast set up your machine, vertical machines come with three settings that are meant to give you more speed. If you’re casting large amounts of platinum, use the quickest settings. Get platinum casting grains from Bullion Trading LLC to customize your platinum jewelry and items as you desire.

The 95.2 Pt. /4.8% Ru and 95% Pt. /5% Platinum Casting Grains

The 95.2 Pt / 4.8Ru % and 95% Pt / 5% Ru platinum casting grains are among the most popular platinum alloys among jewelry manufacturers in the U.S. Both alloys contain Ruthenium which is a grain refiner. It gives the alloys a definite structure. This alloyed platinum has an annealed hardness of 120 HV (Vickers hardness) and a working hardness of about 220HV. The platinum alloy also has high tensile strength.

The three properties of Pt/Ru mentioned above make it suitable for machine casting and polishing. This makes it an excellent alloy in the manufacture of rings. You’ll get a bright-colored platinum jewel or item from the .950 platinum casting grains and pieces.

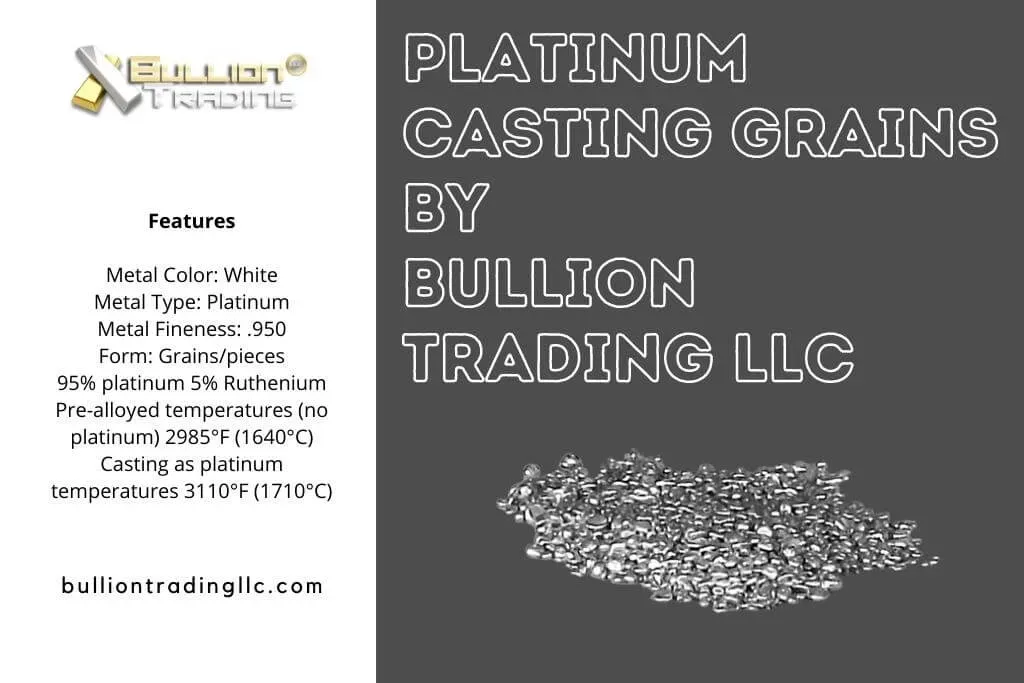

Features & Specifications

- Metal Color: White

- Metal Type: Platinum

- Metal Fineness: .950

- Form: Grains/pieces

- 95% platinum 5% Ruthenium

- Pre-alloyed temperatures (no platinum) 2985°F (1640°C)

- Casting as platinum temperatures 3110°F (1710°C)

Bullion trading LLC stocks Pt/Ru described above. Nevertheless, there’re other popular grains of platinum. For instance, the platinum-containing 10% Iridium is a medium-hard alloy with low ductility, but workable for most manufacturing processes. It’s one of the most popular casting alloys in the U.S because it doesn’t form an oxide film when molten.

However, iridium has the highest melting temperature among the platinum metal groups. The melting temperature for iridium is 2,454°C vs. 1,773°C for platinum. The high temperature required to cast platinum with 10% Iridium can cause slight surface erosion because of metal mold reactions.

Another popular platinum version is the 95% platinum and 5% iridium combination. It’s the softest platinum alloy, but with the least metal mold reactions. The reason some manufacturers prefer this alloy. At Bullion LLC we stock 95.2 pt. /4.8% Ru from Johnson & Matthey and 95% pt. /5% Ru from Umicore.